The Spaces and Timing of Fishing

Geography is a useful way to start considering the environmental history of Columbia River canneries. The spatial and temporal constraints of salmon fishing tell us much about what changed with the advent of commercial fishing. Before 1866, humans harvested salmon over most of the year and throughout the entire Columbia River Basin. Clatsop and Chinook fishers used seines and gillnets to capture salmon from March to October, while Paiute and Spokane used spears, weirs, and baskets from May to November. Because salmon were harvested throughout the year and across the entire region, there was less pressure on any single run, yet the overall harvest still amounted to perhaps as many as 42 million pounds, which rivaled the largest harvests of the late nineteenth century.

Salmon canners thoroughly rearranged the region’s salmon fisheries. Canneries were huge investments in fixed capital, so to recover their costs canners had to locate operations where they could operate on a suitable scale. They needed sites proximate to very large runs of salmon, but they also had to be accessible to freight transportation systems.

At first, the only way to move large amounts of canned salmon was via ocean shipping. This is why Hapgood, Hume and Co., the first canning operation on the river, built its cannery at the otherwise nondescript site of Eagle Cliff in Washington Territory and why, as the 1894 chart by the U.S. Fish Commission in the related documents section shows, the modern fishery rapidly congealed into a tiny portion of the lower Columbia River.

The arrival of the Northern Pacific Railway in 1883 enabled some canners to move east of the Cascade Rapids; but beyond The Dalles, the nature of salmon constrained further migration. The farther upstream salmon swam, the more of their stored body fat they consumed. Beyond Celilo Falls, adult salmon had lost so much fat that they were no longer marketable. Nature and culture thus converged to place firm limits on the geography of the market fishery.

The timing of canning and fishing also shifted. As a strict market calculus, canners could only profit by processing enough salmon to overcome transportation costs to distant markets. The global geography of the salmon trade thus influenced the canneries’ economy of scale, but the nature of salmon also mattered. Fresh fish spoil rapidly, so harvests had to be canned in a hurry. By the 1870s canners were hiring large workforces to process fish, as illustrated by the contract between Seid Chuck and the Seufert Brothers in 1908. Employers needed butchers to process enough salmon for twenty-five thousand cans per day, and solder machine operators to fabricate enough cans to cover the work of two butchers. Such demands reflected not just the onerous burdens on labor but also the natural constraints of a valuable but fragile resource.

Market efficiency and decaying fish cast light on the structure and pace of work. The seasonal nature of cannery operations stemmed from a different merger of nature and culture. Canners learned that spring chinooks were particularly fatty and that consumers preferred this deep red flesh to other runs and species. As a result, they at first confined their fishing efforts to the months of March to June, focusing on spring chinook and sockeye. Other runs and species were thus spared, and can labels emphasized the peculiar provenience and color of Columbia River chinook for consumers.

Natural resources also influenced the industrial and social order inside canneries. Cans were an assembly of Bolivian tin and Missouri lead that laborers first cut and fused by hand. Significant profits hinged on the workers’ ability to produce cans quickly and to seal them so bacteria did not ruin the meat. These were imperfect tasks when done by hand, however, and within a few years industry leaders began to mechanize them. In 1876, they adopted the Howe Soldering Machine, made in England and fueled by charcoal produced from local forests, to fabricate cans faster and more reliably.

Meanwhile cannery labor underwent changes that increasingly reflected racist attitudes about human nature. Until the early 1870s, Columbia canners employed a multi-ethnic labor force, but problems with turnover led William Hume to rely more and more on Chinese laborers, mostly because Asians had few employment options and were more likely to work an entire season. The experiment worked, and other canners began to follow suit.

Industry observers began to view Chinese workers as naturally suited for cannery work because they had hands “as nimble as a woman’s” and were docile, or as federal fisheries researcher John Cobb put it, caused “less trouble.” These ideas accommodated broader notions of racial difference, but the roots of this industrial relationship derived from the contingencies of industrial employment and racial exclusion in the fisheries. They were anything but natural.

Canners struggled constantly to impose an orderly factory system on disorderly nature. They wrote contracts that stipulated the number of fish and cans to be processed each day by each worker, but they could not control the supply of fish. Most of the time canneries operated at less than efficient capacity, often receiving below-optimum supplies during light or delayed runs, only to be overwhelmed during the peak of runs when fishers could deliver over ten times the normal catch. Cannery piers sagged under these harvests, and, as one man noted, workers were “not so much like men struggling with innumerable fish, as like human maggots wiggling and squirming among the swarms of salmon.”

The scale and variability of Columbia River runs caused havoc with the imagined order of a factory. Like other entrepreneurs of the industrial revolution, salmon canners tried to compensate through mechanization. Production accelerated throughout the 1870s and 1880s as automatic can fillers assumed the job of placing fish in cans, rotary washers cleaned the filled cans, and retorts cooked the cans.

Such innovations significantly increased capacity and efficiency, but consumers quickly noticed the difference in the quality of meat packed by hand rather than machine. As a result, canners were forced to retain laborers to pack the gourmet product by hand. As the story of the “Iron Chink” illustrates, the nature of salmon frustrated their attempts to mechanize.

In 1903, Canadian inventor Edmund Smith introduced a machine that would automate the cutting and cleaning of salmon. The device, whose express purpose was to take the place of expensive Chinese butchers, was dubbed the “Iron Chink.” Canners from Puget Sound northward rapidly integrated Smith's machine into their production. North of the Columbia, the sockeye and pink salmon were industry mainstays, and canners could mechanize the butchering of these species because adults ranged little in size. Before the 1930s, however, Columbia chinook normally ranged between fifteen and seventy pounds. No machine could handle such variability, so human labor was still the most efficient way to process the Columbia's magnificent bounty. The biological diversity of salmon thus played a crucial role in the economic management of Columbia River canneries.

© Joseph E. Taylor III, 2006. Updated and revised by OHP staff, 2014.

Sections

Related Historical Records

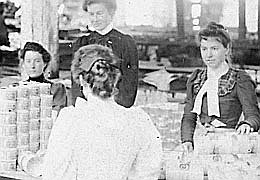

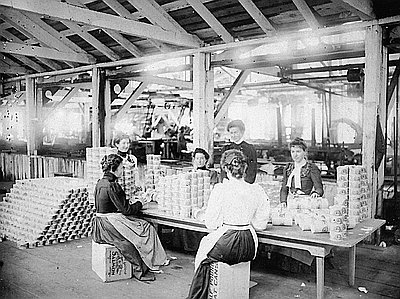

Women Cannery Workers

This photograph was taken by Portland photographer John F. Ford, probably between 1900 and 1902. It shows women labeling cans of salmon at the Megler Cannery in Brookfield, …

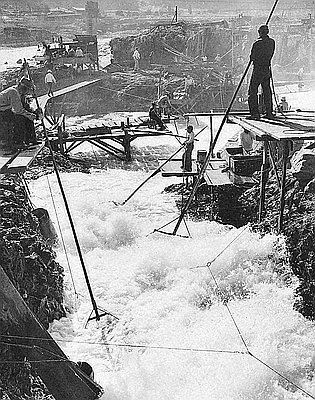

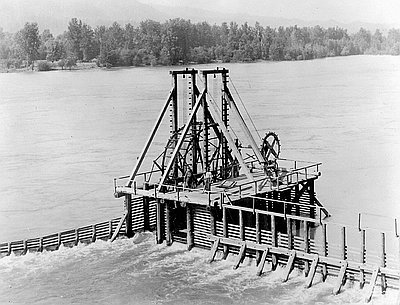

Eagle Cliff Cannery

This photograph shows the Eagle Cliff Cannery, located on the Washington side of the Columbia River about fifty miles upriver from Astoria. During the winter of 1866-1867, brothers …

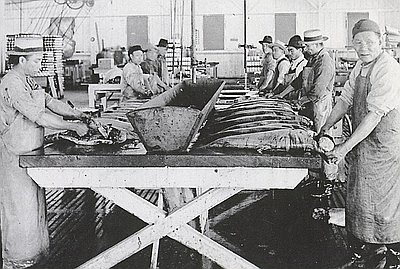

Chinese Workers in Astoria Cannery

This undated photograph of the interior of an Astoria cannery is from the Burlington Northern / Spokane Portland and Seattle Railroad Collection. This promotional photograph conveys the message …